Electrical Distribution

Orbital’s distribution team provides a full range of engineering, design, project management and construction management services to our distribution utility clients. Our substation design projects range from minor modifications such as breaker or switch replacements, to the design of new green field substations. Our team helps our clients inspect, maintain and improve their aerial and underground distribution networks. Our network analysts evaluate complex sectionalized looped circuits with smart substation reclosers controlled by SCADA.

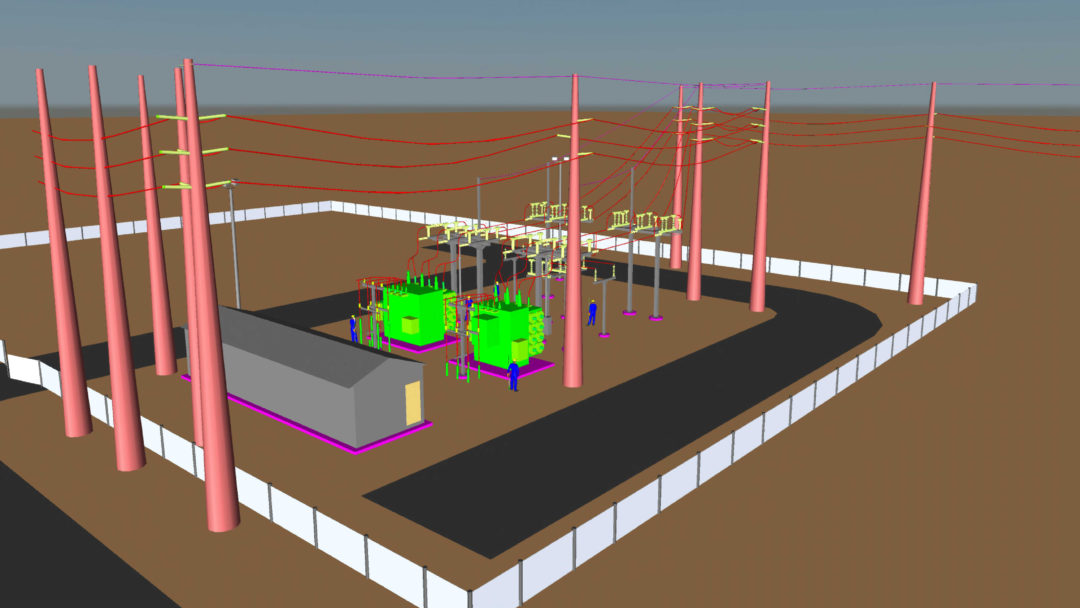

Distribution Substation Design (13.8 kV- 69 kV)

Orbital engineering & design services for distribution voltage level substations parallel those for transmission voltage level substations. The primary difference is the physical scale and often less complex protection schemes.

Due to the reduced physical scale, equipment spacing is often dictated by maintenance considerations as opposed to electrical clearance requirements. The reduced footprint can also pose grounding system design challenges especially in urban areas with high available fault current adjacent to public access areas. Our team of experts recognize and solve these unique conditions on a regular basis.

Network Analysis

Orbital electrical engineering staff routinely evaluates complex electrical power distribution systems using analytical tools such as ETAP, SKM and others. These networks include overhead pole and underground electric distribution systems as well as entire power distribution systems for large industrial clients such as refineries. The system analysis also addresses measures to mitigate arc flash in substation and industrial switchgear. The analysis of electric distribution systems is becoming more complex as utilities employ distribution automation technology to upgrade radial distribution circuits to a looped circuit with sectionalizing switches, employing smart reclosers at the substations that only trip the single faulted phase and utilizing SCADA control. Our network analysis experts are prepared to help our utility clients address these complex issues.

Underground Distribution System Design

Utilities are living with aged underground electric distribution systems with increasing frequency of system faults and service interruptions and need to assess the condition of their network and evaluate the cost of continued repairs or to upgrade the system completely. Orbital has been providing project management and engineering services to our clients to assess the condition of the network, identify line segments and transformers that require replacement, evaluate options to make the distribution system more reliable, and then provide construction management and QA/QC services monitoring the installation contractor. Our team of experts also design extensions of the network required to serve new customers.

Aerial Line Inspection & Design

Orbital’s distribution team has inspected the condition of hundreds of miles of aerial distribution circuits. Our detailed reports identify the condition, location and severity of identified deficiencies and provide recommendations for repair or further observations. Upon client authorizations, Orbital will design the modification such as reconductoring and/or reinsulating circuits to increase the design voltage or ampacity. We also design new pole line routes whether for a new residential subdivision, new industrial service or to tie the remote ends of two radial distribution lines together.

Power Distribution Reliability Programs

Orbital assists electric distribution utilities in implementing their power delivery reliability programs. Typical programs include substation improvements, underground distribution system upgrades, radial line sectionalizing with SCADA control, looping radial lines from two (2) different substation sources and recloser replacement with smart reclosers.

Substation reliability is impaired by aging equipment, geophysical conditions and operational challenges. Equipment replacement may be required due to a history of excessive maintenance, lack of replacement parts or water intrusion. Water intrusion may be due to existing grading and drainage deficiencies, changes in river and stream flood elevations or leaking roofs. Grading and drainage conditions also may impact the safety of operation personnel. Orbital’s substation design team assists clients to remediate these adverse conditions and improve that substation’s power delivery reliability.

Underground power distribution systems for many utilities have reached or exceeded their end of useful life. Increased frequency of outages and repairs due to cable faults and pad mounted transformer deterioration result in a decrease in power delivery reliability and an increase in maintenance costs. Orbital assists our electric distribution utilities in the repair and replacement of these systems. Our support may start with a Program Management Assessment identifying what parts of the system require replacement. We supervise qualified electrical contractors who safely isolate, inspect and test the cables and transformers. The project’s daily progress is uploaded to our cloud database where clients can generate custom reports daily. Upon authorization to repair or replace the components identified by the above assessment, Orbital again monitors the progress of the installation and testing contractors until the project is completed. Similarly, daily progress is uploaded to the database and available to the client contemporaneously.

Radial distribution lines, once they leave the substation, are vulnerable to faults due to pole mounted equipment failures, animal generated faults, tree impacts or traffic accidents. When such faults occur, the local segment of the line is isolated for repair and the segments past the fault area are without power until the fault is cleared. To improve reliability, two radial lines from different substation sources are tied together at the far end with additional SCADA controlled sectionalizing switches installed along the routes. This enables the utility to isolate a smaller faulted segment and back feed the segments past the fault from the other substation source. Orbital’s qualified team helps the utility with the routing and design of the line tie segment, the design and location of the sectionalizing switches and the design of the SCADA communication and controls.

Distribution lines exiting a substation are protected by a recloser and isolating switches at the substation. Traditional reclosers, upon detecting a fault on the line or receiving a trip signal, will open all three phases of the outgoing distribution circuit. Modern smart reclosers will identify the faulted phase and only isolate that phase. This reduces the impact to customers by 2/3. This requires that remotely generated trip signals also identify the faulted phase. Orbital’s experienced substation design team designs the modifications at the substations and the communication upgrade required to support the revised system.

Joint Use

As communication system developers continue to build out their networks they frequently apply to the owners of existing utility poles for permission to attach their copper or fiber cables to the poles. The advantage to the owner of the utility pole is future rental revenue paid to the owner by the developer/attacher. However, depending on the state regulations the pole owner may have to respond to the requestor in a short period of time. Electric utilities who own the majority of the utility poles do not have adequate staff to meet the demand within the mandated schedule.

Orbital’s Joint Use Teams provide the skilled resources to help the owner meet their regulatory deadlines. The following is the key steps in the process

- The developer submits an application to the pole owner identifying the route, poles and type of attachment.

- The application is submitted electronically in packets ranging from 2 to 75 poles per packet. A complete project may require the submittal of multiple packets.

- The pole owner then assigns a group of packets to Orbital to process.

- Orbital then

- Downloads and reviews the packets

- Plans the review route

- Walks the route, taking pictures and field data

- Evaluates each pole in the office for acceptability of the requested attachment and its compliance to the pole owner’s standards or identifies work needed for the attachment to comply with the standards

- Utilizing the pole owner’s proprietary system, develops the cost of the owner to accommodate the developer’s request for the specific packet.

- Upon agreement between the pole owner and developer and payment of the required amount, Orbital then prepares the work orders (make ready) for each pole modification

- The pole owner then employs a qualified contractor to implement the required changes.

- Upon completion of the required modifications, Orbital provides QA/QC services, verifying on behalf of the pole owner that the installation complied with the work orders.

- Pole owners also will request Orbital to provide turnkey services by bringing the installation contractor under Orbital’s contract.

UAV Inspection

Unmanned Aerial Vehicle (UAV) Inspections combined with Alignment Surveys of Crane Runways Orbital Technical Solutions (OTS) provided Asset Integrity Services with use of Unmanned Aerial Vehicles (UAVs) and survey equipment. The equipment was used to complete visual...